source:other news release time:2023-03-23 Hits: Popular:led screen wholesaler

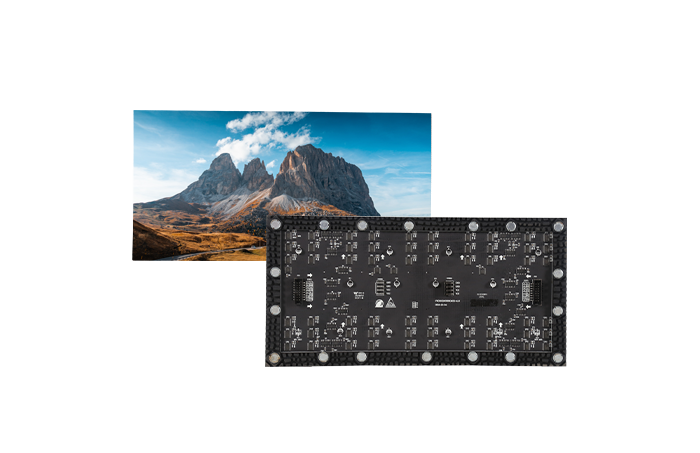

In the past, the full -color LED display is a fresh object in everyone's eyes. As the market applications are becoming increasingly well known, how much do you know about the basic production process of full -color LED display?

We have to make the LED display. First of all, we have to prepare the materials. Today, the editor has collected a LED display to install the production manufacturing process to explain the materials and processes of the displayed screens. A display screen covers the part of the outer frame, showing parts, controlling parts, local power supply and small accessories.

1. Local frame: Special aluminum profile, corner, light steel keel, rear baffle (aluminum -plastic board, Ou Song board)

2. Show part: unit board. Attachment covers: Vowial power cord.

3. Cutting parts: stretching cards, turning panels, cables. Note! (Individual control cards do not need to be connected and lines)

4. Power supply local: 220V-5V power supply. The commonly used is 40A and 30A. Start the work status.

5. Small accessories: 16P lines, 16P card heads and cards, three -core value line, DB9 head (needle, hole) DB9 glue case, power cord, self -attack wire. Strong iron -sucking stone (pillars and magnetic movies)

6. Tools: cutting machine, threading tongs, electric soldering iron, stripping tongs, cone conclusion.

Read recommendations:

indoor led display screen modules company

LED Grille Screen company.What are the effects of high temperature operation on LED electronic scree

p6 waterproof rental cabinet price.The promotional value of touch screen all-in-one machines