source:other news release time:2023-03-22 Hits: Popular:led screen wholesaler

1. Driving mode: the driving mode of indoor full-color led display is constant current driving, and dynamic scanning mode is adopted (mainly 1/4, 1/8 and other scanning modes). With the same tube core, more circuits are used for 1/4 scanning, and the brightness is also higher.

2. Real pixel and virtual pixel. Like the outdoor full-color screen, the number of pixels of the indoor full-color screen is also divided into real pixels and virtual pixels.

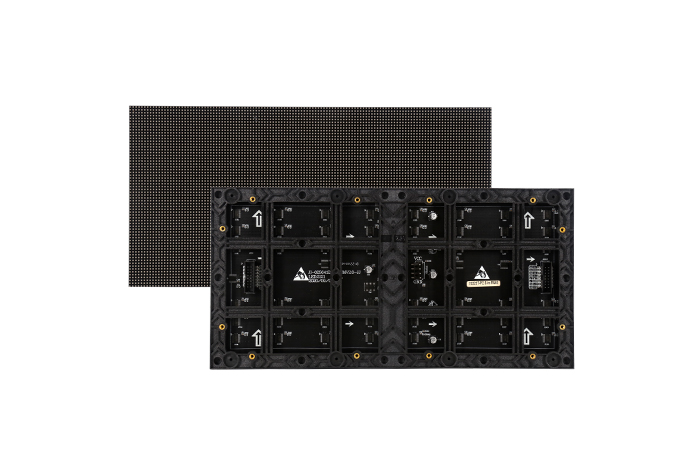

3. Density: Due to the large heating capacity of indoor full-color led chips and the high density of control circuits, the point density of commercial full-color screens can not be very high, mainly including P5, P6, P7.62, P8, P10, etc.

4. Tube core. As with the outdoor full-color screen, it is generally recommended that the blue and green tubes of the indoor full-color display screen adopt the core of Styrofoam, and the red tubes adopt the core of Guanglei or Guangjia. For high-end products, it is recommended to use the core of Japanese Riya and American Cree.

5. Packaging form. LED surface forms of indoor full-color LED display include single lamp, sub-surface sticker, three-in-one surface sticker and three-in-one surface sticker, and the appearance is also different. The advantages of surface mount packaging are large viewing angle, good luminous uniformity, and easy automatic welding processing. It is the mainstream product of full-color led screen, but the price is relatively high now; The single-lamp viewing angle is relatively small, the brightness is slightly high, and the price is low. Sub-table sticker is also a kind of single lamp. Single lamp and sub-surface sticker are relatively cheap and are transitional products.

Read recommendations:

rental led display manufacturer